Discover: Thermoset Composite Materials Solutions & Applications

What if the materials around us could be reimagined, engineered to meet the precise demands of any application, and manufactured with both performance and sustainability in mind? The answer lies within the versatile world of thermoset composite materials, a realm where innovation knows no bounds, and the possibilities are truly transformative.

The journey begins with collaboration. At the heart of this process lies a deep understanding of the client's needs. The initial step involves working closely with designers. This collaborative approach is crucial, as it allows us to identify the best material and process options, ensuring the final product meets the specific requirements of the application. From the outset, the team establishes a design validation and verification plan. This meticulous approach ensures that every aspect of the design, from the material selection to the manufacturing process, is carefully considered and rigorously tested.

This dedication to quality extends to the manufacturing process itself. All this is done with economics and ongoing mass production in mind from the start. The aim is to create materials that are not only high-performing but also cost-effective and easily scalable for large-scale production. This forward-thinking strategy ensures that the solutions provided are practical, sustainable, and deliver long-term value to clients.

To meet the growing demand, there is a global footprint, with a focus on supporting specific markets. To support the demand for thermoset composite materials in Asia, the company has expanded its operations. This global presence allows for better service to the clients and allows for the utilization of diverse resources and capabilities.

For those seeking a deeper understanding, there is a commitment to providing comprehensive information. Learn more about their products, material development, and markets served. This commitment to transparency and knowledge sharing demonstrates a dedication to not only manufacturing top-quality materials but also educating and empowering clients to make informed decisions.

Norplex Micarta, a leading name, sets the standard. Norplex Micarta is one of North America's leading producers of thermoset composite prepregs, sheets, and shapes. From their global headquarters in Postville, Iowa, to their satellite plant in Changzhou, China, the company operates a robust manufacturing network. This dual-location strategy allows them to serve both North American and Asian markets efficiently, providing localized expertise and support.

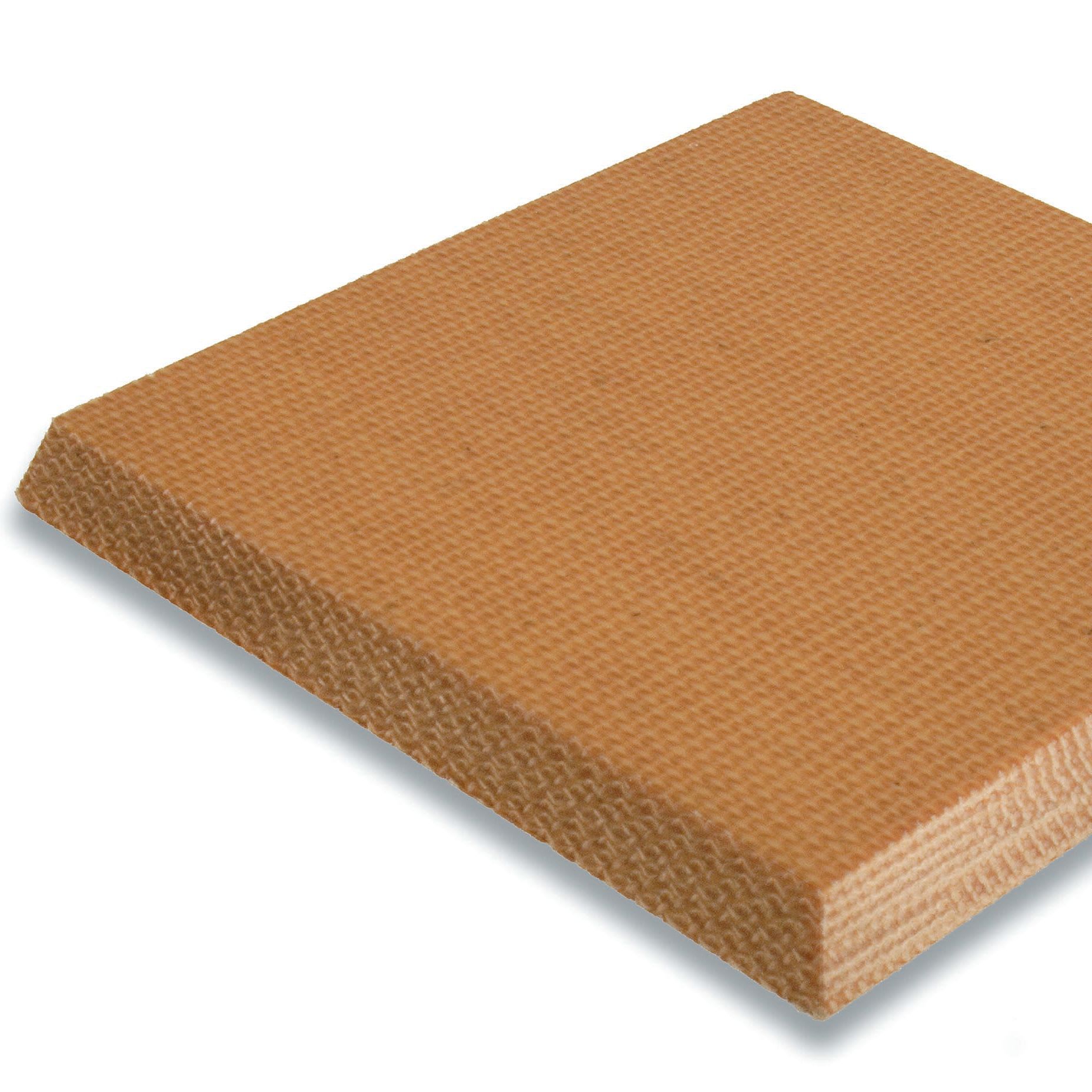

One of the key materials in their lineup is Ultrex Micarta, a material with a rich history. Ultrex Micarta is the original knife handle material and a laminated composite of paper and cotton fabric reinforced phenolic. It offers a range of products, including Ultrex, a family of composite materials for aesthetic applications such as knife handles and gun grips. In fact, the trade name Micarta is synonymous with phenolic resin matrix reinforced paper and cotton fabric materials. It showcases the company's expertise in creating materials that are not only functional but also visually appealing.

The range of materials extends far beyond phenolic. But we produce much more than just phenolic materials. Some types can be punched using cold punching dies, while others can be machined with normal metalworking tools. These materials are engineered to meet various needs, from industrial applications to aesthetic components.

The applications of these composite materials are vast and varied. Applications include bearings, high-temperature gaskets, industrial gaskets, washer/bolt/flange insulation components, cryogenic applications and more. This versatility underscores the adaptability and the potential of these materials to improve performance across different industries.

For inquiries and support, the company has a dedicated address: 665 Lybrand Street, PO Box 977, Postville, Iowa, 52162. This address serves as a central hub for communication, ensuring that clients can easily access the support and information they need.

The materials are further enhanced through the use of additives. These resin systems can be modified through the use of various additives to modify their behavior. These additives can make the material semi to fully conductive, increase the hardness, increase the toughness, or reduce the material's density. This ability to tailor the properties of the materials allows for precision engineering, ensuring that each material is perfectly suited to its intended application.

To serve the Asian market, a dedicated manufacturing facility is in place. Changzhou Micarta Composite Material Company is the name of the dedicated company. This ensures that there are sufficient capabilities to support the demand in Asia.

The dimensions of the products are precisely controlled. Minimum internal diameter is 0.625 inches (1.6 mm) and maximum outside diameter is limited to 5 inches (127 mm). Wall thicknesses can vary and will depend on the ID and OD. Minimum wall thickness is 0.085 inches (2.2 mm) and maximum wall thickness is determined by design requirements.

The company's materials are designed to be utilized in nearly limitless applications. Utilizing several different resin systems on nearly limitless different applications. This underlines the company's capability to customize and adapt its materials to suit a wide array of needs and circumstances.

The company takes pride in its customer-centric approach. As a materials company, we are focused on understanding the needs of a specific application, supporting designers, and providing ongoing value to clients that utilize our products. This strategy promotes a partnership-based approach, establishing long-term partnerships. They aim to provide the best product for their customers.

The history of these materials spans nearly a century, demonstrating their enduring value. Thermoset composites have nearly one hundred years of use in electrical equipment. This long-standing presence is a testament to their reliability and their continued relevance in a fast-evolving world.

The materials come in different forms, ready for various applications. In addition to full sheets at many different thicknesses that are in stock in our warehouses, the company provides various products. This ensures the materials are available when required.

The aerospace industry utilizes these materials for safety and efficiency. The glass window mounts into the composite frame, which is then bolted to the aluminum skeleton of the aircraft. The frame must withstand the impact force of installation and provide excellent mechanical strength. This highlights the materials' capabilities in high-stress environments.

These materials also play an important role in infrastructure. Thermoset composite materials are also used in cryogenic pipeline insulation and support, and in cryogenic storage vessels, bunkering tanks, and LNG carriers. This shows their importance in supporting the development of new energy technologies.

The Postville, Iowa, facility is central to the production process. Resin systems based on epoxy, phenolic, melamine, and silicone are commonly ran in our Postville, Iowa facility. These and other resin chemistries are often modified with additives to provide custom solutions. This shows the extensive manufacturing capabilities.

Important information is provided to clients about the closure. Holiday closure our offices will be closed for Memorial Day Fri., May 27th, as we remember and honor our nation's heroes. This demonstrates the company's respect for holidays and its commitment to its employees.

Finally, the company's address is reiterated for easy access: 665 Lybrand Street, PO Box 977, Postville, Iowa, 52162. This is a focal point of all communications.

| Property | Details |

|---|---|

| Company Name | Norplex Micarta |

| Headquarters | Postville, Iowa, USA |

| Satellite Plant | Changzhou, China |

| Core Products | Thermoset composite prepregs, sheets, and shapes; Ultrex Micarta (knife handle material) |

| Resin Systems | Epoxy, Phenolic, Melamine, Silicone (and others, modified with additives) |

| Key Applications | Knife handles, gun grips, bearings, gaskets, insulation components, cryogenic applications, aircraft components |

| Materials Used | Phenolic resin matrix reinforced paper and cotton fabric, various thermoset composites |

| Manufacturing Capabilities | Cutting, Machining, Cold Punching |

| Diameter Specifications | Minimum ID: 0.625 inches (1.6 mm); Maximum OD: 5 inches (127 mm) |

| Wall Thickness Specifications | Minimum Wall Thickness: 0.085 inches (2.2 mm) |

| Address | 665 Lybrand Street, PO Box 977, Postville, Iowa, 52162 |

| Key Features | Collaboration with designers, design validation, mass production focus, wide range of applications |

| Website Reference | Example Norplex Micarta Products Page |